Electrical Control of a Mine

| < Submarine Mines deployed in anger | Δ Index | Layout of a Minefield > |

Both observation and contact mines were detonated using electricity. The power was supplied by sets of batteries in the shore station – no national grid! Each mine was connected to the shore station by a single electric cable, with the return path being through the “earth” i.e. the surrounding sea-water.

To detonate a mine, an electric current was passed through the cable to a platinum-wire fuse in the mine.

The fuse heated up, became incandescent, and ignited a surrounding layer of detonating explosive (fulminate of mercury) the detonating charge.

This in turn then ignited a primer of 4 ½ lb (2 kg) of gun-cotton. These inner components – fuse, detonator and primer charge, were contained in a sealed steel container, call the apparatus.

The detonation of the primer charge ignited the main charge of guncotton.

For a Contact Mine, moored on cable to float just beneath sea level at low tide, the main charge was 100lb (45 kg) of gun cotton. In contrast Observation Mines sat on the sea bed, so required a larger charge, 250 lb (113 kg) in water at a depth of less than 36 feet (11 m) or 500lb (227kg) in water of less than 60 feet (18m.)

The whole thing was of course contained in a steel outer casing.

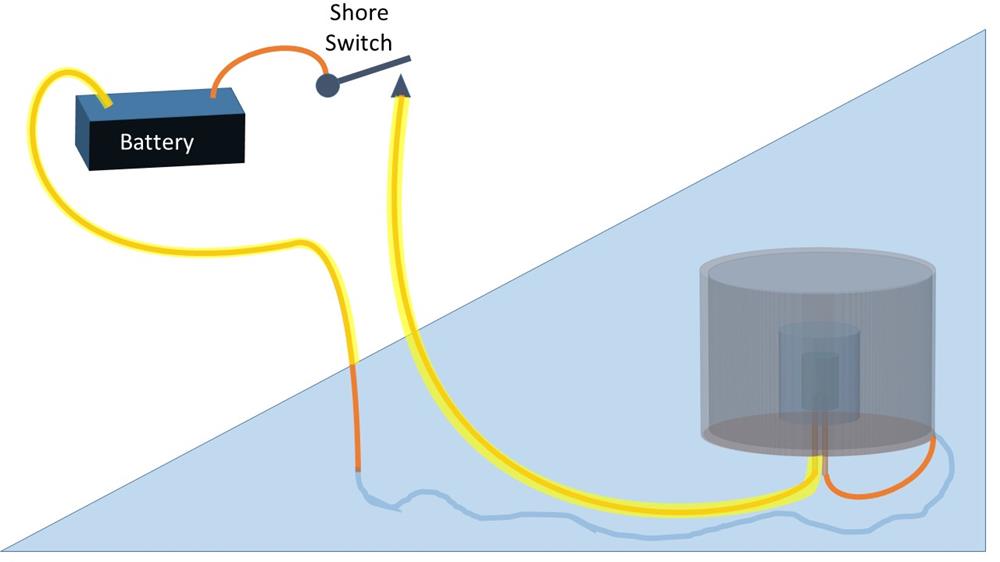

This is the simplest configuration for an observation mine. On spotting an enemy ship over the position of the mine, the shore switch is closed. Current flows from the battery through the fuse in the mine, and back via the earth return path – through the sea water. The fuse heats up and the mine explodes.

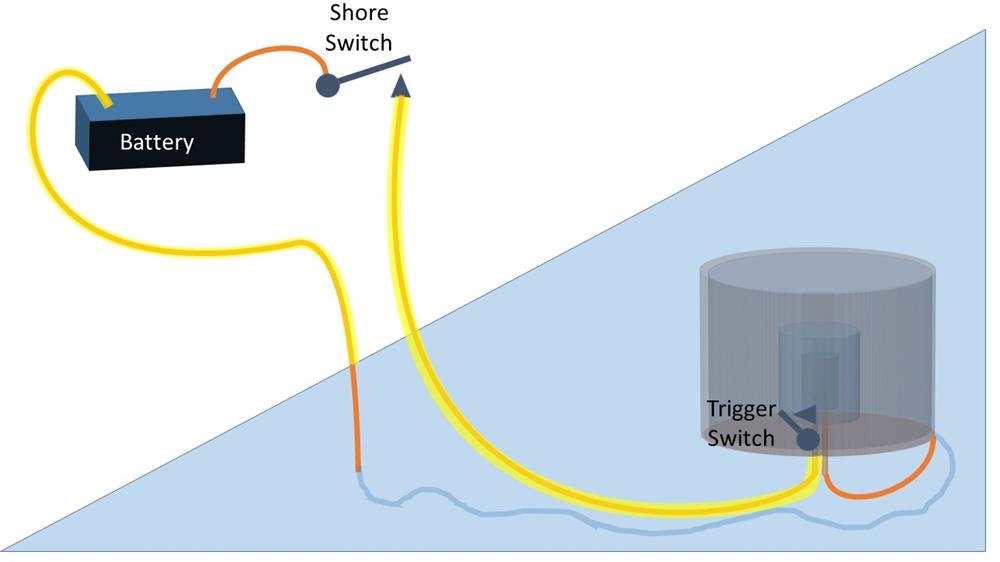

A contact mine requires an additional trigger switch in the mine, which is closed when the mine is struck. During the day, the shore switch is open, so no electricity will flow even when the trigger switch is closed. At night, with the shore switch closed, the mine is active and will explode when struck.

In practise, life was inevitably more complicated.

If a cable was broken, by snagging on the sea-bed, being dragged by passing ships, or even sabotage, the connection would be “open-circuit” so current could not flow and the mine would not explode.

If the cable insulation was damaged, sea-water would short-circuit the connection, the current would not pass through the fuse and the mine would not explode.

Electrical Cable

Cable technology was still in its infancy, no popping in to B&Q or Screwfix for a reel of plastic insulated power cable!

The cable was the longest in the world at the time.

From The Scotsman Tuesday 23rd January 2018]

Each mine was connected to the shore station using a single-core cable. This core was made up of seven strands of copper, each strand being tinned, to protect the copper from the corrosive effects of the insulation.

The copper core was then insulated using Hooper’s Material. This consisted of an inside coating of pure India rubber, then a separator layer which was another coating of India rubber combined with zinc oxide, and finally an outside coating of India rubber combined with sulphur. The separator prevents any damage to the conducting wires by the action of the sulphur. The three coatings were then baked for some hours at a very high temperature, which fused the whole into a solid mass, and vulcanised the outer coating.

This created a tough outer layer of vulcanised rubber, and a flexible inner layer of insulating pure India rubber. The cable was then wrapped in a protective sheath of hemp, followed by a steel-wire armour layer to guard against cable damage by the action of currents, or snagging on rocks, and a final outer sheath of braided hemp.

This was Cadell’s “long cable of copper-cored twine” from the Company Song.

The return path for the electric current from each mine was by “earth” i.e. through the surrounding sea-water.

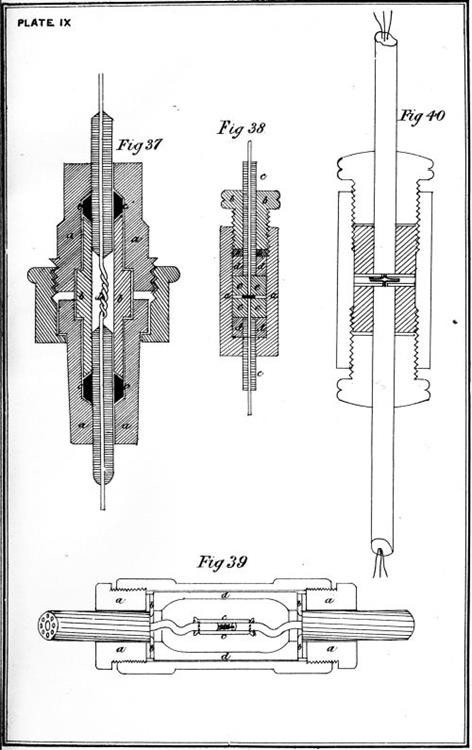

The cables were laid in sections, necessitating joints which could withstand immersion in sea-water.

This was not straightforward.

Soldering was used at first, but this is difficult in an open boat at sea, and a simple twisted joint proved to be satisfactory.

Insulation of the joint involved wrapping it in layers of India rubber, stuck together with India-rubber solution.

The joint was then encased in a protective junction box.

Once the cable was connected from the mine to the shore station, it was necessary to test the connection on more or less a daily basis to ensure that the cable had not broken, or that sea-water had not intruded, which would short circuit the connection.

In fact this single strand cable connection had to serve three purposes:

1. to test the connection from shore station to the mine.

2. to signal from the mine to the shore station that a mine had been struck

3. to detonate the mine from the shore station.

These three functions were achieved with some clever electro-mechanical pieces of equipment. (long before the days of electronic valves and transistors!)

The details of the electrical systems are covered in an appendix on this subject.

| < Submarine Mines deployed in anger | Δ Index | Layout of a Minefield > |